Description

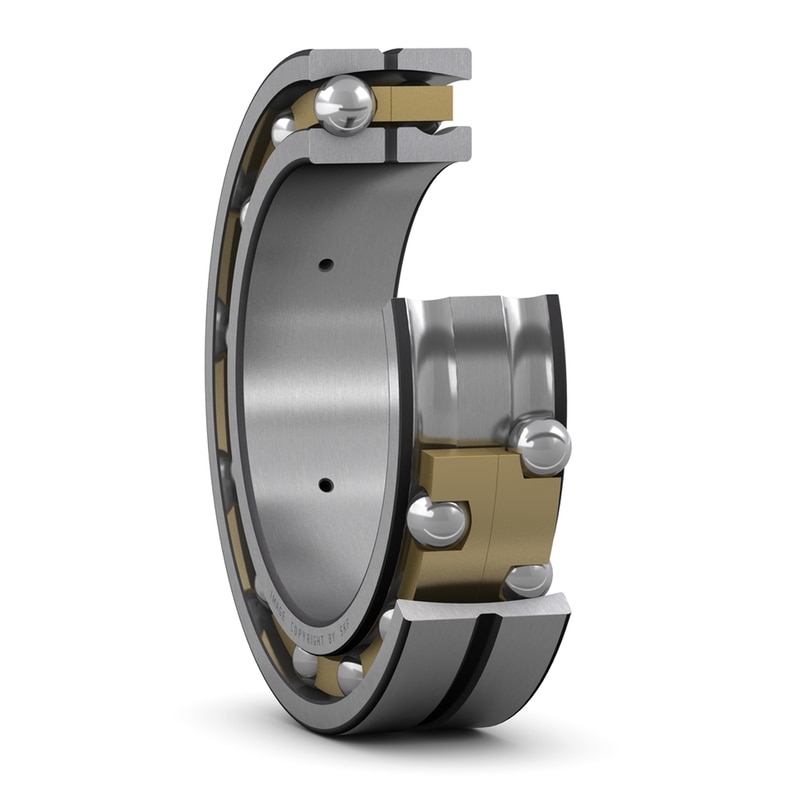

The structure of an angular contact ball bearings with WRM brand consists of an inner ring, an outer ring, a set of balls, and a cage. The inner and outer rings have raceways, which are grooves that the balls roll along. The cage holds the balls in place and prevents them from coming into contact with each other.

The function of an angular contact ball bearing is to support both radial and axial loads. The contact angle between the raceways and the balls allows the bearing to handle high axial loads while still maintaining a high radial load capacity. The contact angle also affects the speed and accuracy of the bearing. Bearings with a larger contact angle can handle higher axial loads but have lower speed and accuracy, while bearings with a smaller contact angle have higher speed and accuracy but lower axial load capacity.

Angular contact ball bearings with WRM brand can be designed with different contact angles, such as 15°, 25°, or 55°, depending on the application requirements. They can also be designed as single-row or double-row bearings, with different cage designs to accommodate different load and speed requirements.

Overall, the structure and function of angular contact ball bearings make them ideal for high-speed and high-precision applications where both radial and axial loads need to be supported.