Description

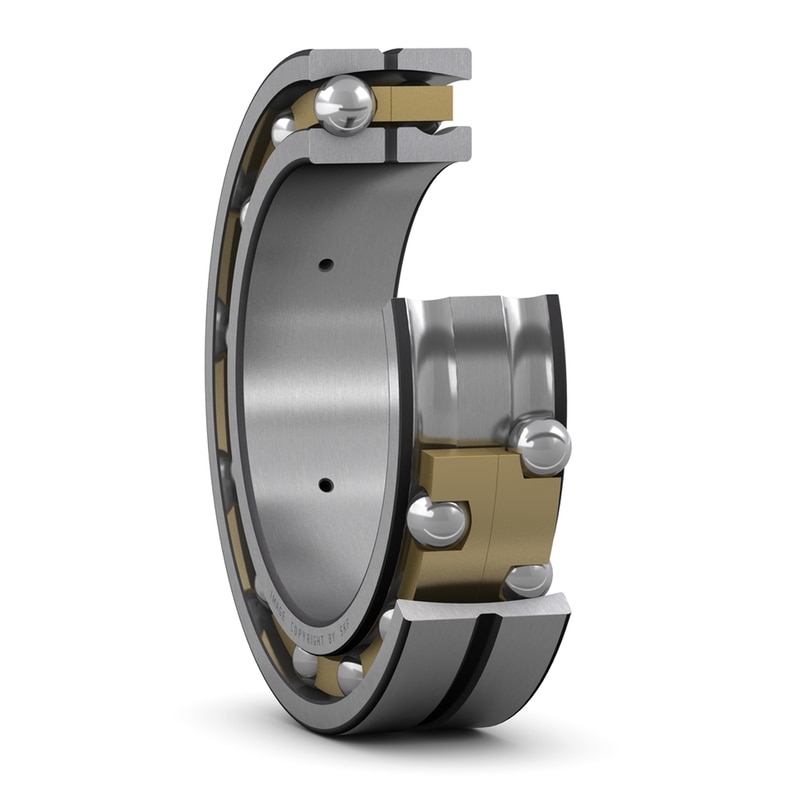

1. Double row configuration: A double row cylindrical roller bearing consists of two sets of cylindrical rollers arranged in parallel, providing increased load carrying capacity and improved radial stiffness compared to a single row bearing.

2. High radial load capacity: The double row design allows for a higher number of rollers, resulting in a greater radial load carrying capacity. This makes double row cylindrical roller bearings suitable for applications with heavy radial loads, such as in industrial machinery and equipment.

3. Improved axial load capacity: In addition to their high radial load capacity, double row cylindrical roller bearings also have the ability to accommodate certain axial loads. This makes them suitable for applications where both radial and axial loads are present, such as in gearboxes and transmissions.

4. High rigidity: The parallel arrangement of the rollers in a double row cylindrical roller bearing provides increased rigidity and stiffness, allowing for better resistance to deflection under heavy loads. This helps to maintain the accuracy and precision of the bearing’s operation.

5. Separable design: Double row cylindrical roller bearings are often designed with separable inner and outer rings, allowing for easier installation, removal, and maintenance. This feature also facilitates the replacement of individual components without the need to replace the entire bearing assembly.

6. High-speed capability: Double row cylindrical roller bearings are capable of operating at high speeds, thanks to their optimized internal design and advanced cage options. This makes them suitable for applications where rotational speeds are high, such as in electric motors and machine tool spindles.

7. Enhanced lubrication: Double row cylindrical roller bearings can be equipped with various lubrication options, including grease or oil lubrication, to ensure proper lubrication and minimize friction and wear. This helps to extend the bearing’s service life and improve its overall performance.

8. Versatility: Double row cylindrical roller bearings are available in various designs and sizes to accommodate different application requirements. They can be found in a wide range of industries, including automotive, aerospace, mining, and construction.

1. Gearboxes and transmissions: Double row cylindrical roller bearings are commonly used in gearboxes and transmissions of various types of machinery, including automobiles, trucks, and industrial equipment. They provide reliable support for both radial and axial loads, ensuring smooth and efficient power transmission.

2. Machine tool spindles: Double row cylindrical roller bearings are often employed in machine tool spindles, which require high precision and high-speed operation. Their high rigidity and ability to withstand high rotational speeds make them ideal for this application.

3. Industrial machinery: Double row cylindrical roller bearings are widely used in various types of industrial machinery, such as pumps, compressors, and fans. They can handle heavy radial loads and provide excellent performance in demanding operating conditions.

4. Construction equipment: Double row cylindrical roller bearings are commonly found in construction equipment, such as excavators, cranes, and bulldozers. Their ability to handle heavy loads and withstand harsh working environments makes them suitable for these applications.

5. Mining equipment: Double row cylindrical roller bearings are used in mining equipment, including crushers, screens, and conveyors. They can withstand heavy loads and vibrations, ensuring reliable performance in the challenging conditions of mining operations.

6. Wind turbines: Double row cylindrical roller bearings are utilized in the main shaft and gearbox of wind turbines. They provide the necessary support for the rotating components and can handle the high loads and speeds associated with wind energy generation.

7. Paper and pulp industry: Double row cylindrical roller bearings are commonly used in paper and pulp processing equipment, such as paper machines and pulp digesters. They can handle the heavy loads and high speeds involved in these applications.

11. Railways: Double row cylindrical roller bearings are employed in railway applications, including locomotives and passenger trains. They provide reliable support for the wheels and axles, ensuring smooth and safe operation.

Overall, double row cylindrical roller bearings find applications in a wide range of industries and machinery that require high load carrying capacity, high-speed capability, and reliability in demanding operating conditions.