Description

Cam rollers, also known as track rollers or cam followers, are specialized bearings designed for applications where linear motion or rotation is required. They feature several distinct features that make them suitable for these applications:

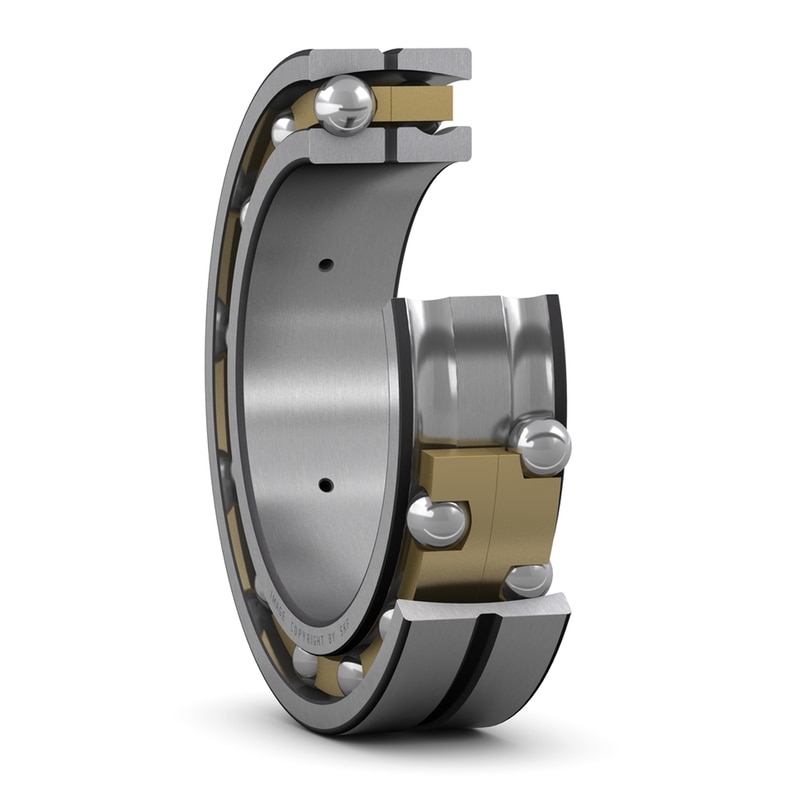

1. Outer ring: Cam rollers have an outer ring that is typically cylindrical in shape. This outer ring acts as a track or guide for the roller, allowing it to move smoothly along a predetermined path.

2. Roller: The roller of a cam follower is typically cylindrical or barrel-shaped. It is designed to roll along the outer ring, providing smooth and low-friction motion.

3. Stud or shaft: Cam rollers usually have a stud or shaft attached to the center of the roller. This stud or shaft provides a means of attachment to the machine or structure, allowing the cam roller to be mounted and secured in place.

4. Sealing: Cam rollers often feature sealing elements, such as rubber seals or shields, to protect the internal components from contamination and prevent lubricant leakage.

5. Lubrication: Cam rollers require proper lubrication to ensure smooth operation and reduce friction. They may have grease fittings or lubrication holes to facilitate easy lubrication.

6. High load capacity: Cam rollers are designed to handle high radial loads, making them suitable for applications with heavy loads and high shock or impact forces.

7. Versatility: Cam rollers are available in various sizes, designs, and materials to suit different application requirements. They can be made from different types of steels, stainless steel, or even plastic, depending on the specific application needs.

8. Easy installation: Cam rollers are typically designed for easy installation. They often have a threaded stud or shaft, allowing them to be easily mounted and secured in place using nuts or other fasteners.

9. Customization: Cam rollers can be customized with additional features, such as eccentric collars or special coatings, to meet specific application requirements.

10. Wide range of applications: Cam rollers are widely used in various applications, including conveyor systems, cam mechanisms, packaging machinery, printing presses, material handling equipment, and more.

Overall, cam rollers offer reliable and efficient motion control in applications that require linear motion or rotation. Their features, such as the outer ring, roller, stud or shaft, sealing, lubrication, high load capacity, versatility, easy installation, customization options, and wide range of applications, make them a preferred choice in many industries.

Cam rollers, also known as track rollers or cam followers, have a wide range of applications in various industries. Some of the common applications of cam rollers include:

1. Conveyor systems: Cam rollers are commonly used in conveyor systems, where they provide smooth and reliable motion for the movement of goods or materials along a track.

2. Packaging machinery: Cam rollers are utilized in packaging machinery, such as filling machines, labeling machines, and carton sealing machines, to ensure precise and controlled motion during the packaging process.

3. Material handling equipment: Cam rollers are used in material handling equipment, including forklifts, pallet jacks, and overhead cranes, to facilitate the movement and positioning of heavy loads.

4. Printing presses: Cam rollers are employed in printing presses to guide the movement of paper or other printing materials, ensuring accurate and consistent printing.

5. Cam mechanisms: Cam rollers are an integral part of cam mechanisms, which are used in various applications such as indexing tables, rotary indexing drives, and cam-driven machines. They provide controlled and precise motion based on the shape of the cam profile.

6. Textile machinery: Cam rollers find application in textile machinery, such as spinning machines and weaving looms, to guide the movement of threads or fabrics during the manufacturing process.

7. Automotive industry: Cam rollers are used in automotive applications, including engine components, suspension systems, and steering mechanisms, to provide smooth and reliable motion.

8. Agricultural machinery: Cam rollers are employed in agricultural machinery, such as harvesters and tractors, to facilitate the movement of various components and ensure efficient operation in demanding outdoor conditions.

9. Construction equipment: Cam rollers are utilized in construction equipment, such as excavators, loaders, and cranes, to provide reliable and smooth motion for various moving parts.

68. Robotics: Cam rollers are used in robotic systems to facilitate precise and controlled motion, allowing robots to perform tasks with accuracy and efficiency.

These are just a few examples of the many applications of cam rollers. Their ability to provide smooth and reliable motion makes them suitable for a wide range of industries and machinery where linear motion or rotation is required.