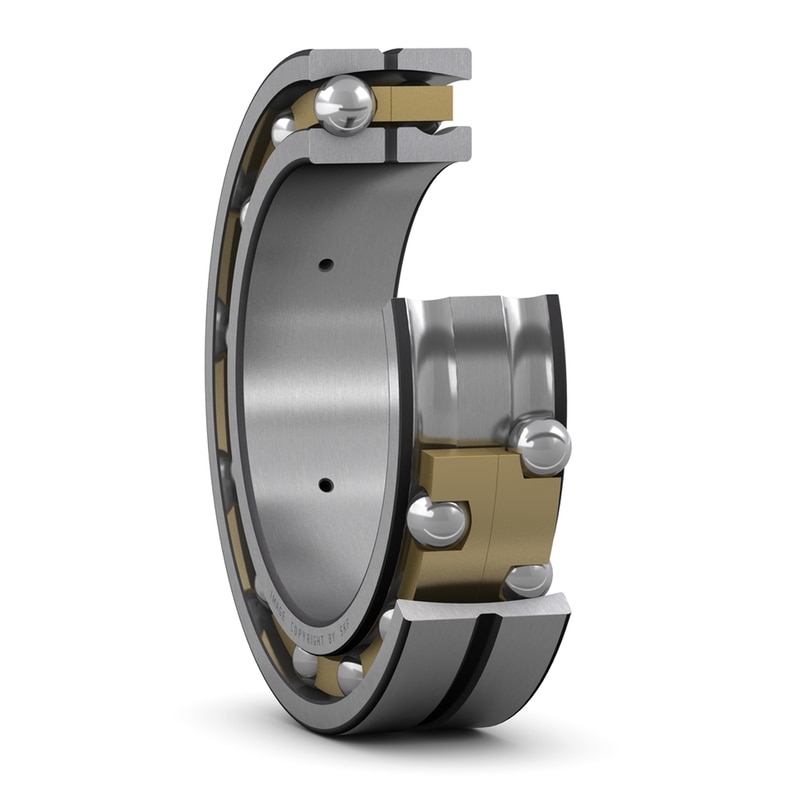

BTM 100 BTN9/P4CDB

Super-precision double direction angular contact thrust ball bearing

Super precision double direction angular contact ball bearings are designed to locate spindle shafts axially in both directions. They can accommodate axial forces in both directions and are available in two main designs: BTW (the basic series bearings, which accommodate greater axial loads) and BTM (the high-speed series bearings, which accommodate higher speeds).

- Very high running accuracy

- High axial load carrying capacity in both directions

- High axial rigidity

- Two main designs to accommodate greater load carrying capacity or rigidity and speed

Description

Dimensions

| d | 100 mm | Bore diameter |

|---|---|---|

| D | 150 mm | Outside diameter |

| H | 45 mm | Height |

| d1 | 123 mm | Shoulder diameter shaft washer (high shoulder) |

| D1 | 137.1 mm | Shoulder diameter housing washer (low shoulder) |

| r1,2 | min. 1.5 mm | Shaft washer chamfer radius |

| r3,4 | min. 1 mm | Housing washer small chamfer radius |

Abutment dimensions

| da | min. 107 mm | Abutment diameter shaft |

|---|---|---|

| Da | max. 145 mm | Abutment diameter housing |

| ra | max. 1.5 mm | Fillet radius |

| rb | max. 1 mm | Fillet radius |

| dn | 119.7 mm | Oil nozzle position |

Calculation data

| Basic dynamic load rating | C | 48 kN |

|---|---|---|

| Basic static load rating | C0 | 116 kN |

| Fatigue load limit | Pu | 4.3 kN |

| Attainable speed for grease lubrication | 5 600 r/min | |

| Attainable speed for oil-air lubrication | 7 100 r/min | |

| Contact angle | α | 40 ° |

| Preload class A | 550 N | |

| Preload class B | 1 650 N | |

| Axial stiffness for preload A (sets of two brgs back-to-back or face-to-face) | 534 N/µm | |

| Axial stiffness for preload B (sets of two brgs back-to-back or face-to-face) | 809 N/µm | |

| Reference grease quantity | Gref | 22 cm³ |

Speed values are applicable to bearings with light preload (suffix DBA). For bearings with a heavy preload (suffix DBB), attainable speeds are about 75% of the quoted values. |

Mass

| Mass bearing | 2.65 kg |

Tolerances and clearances

Bearing data

- Tolerances: P4C, SP, UP

Principles of bearing selection and application

- Chamfer dimensions

- Seat tolerances for standard conditions: shafts, housings

- Values for ISO tolerance classes: shafts, housings

- Speed dependent initial grease fill → Initial grease fill