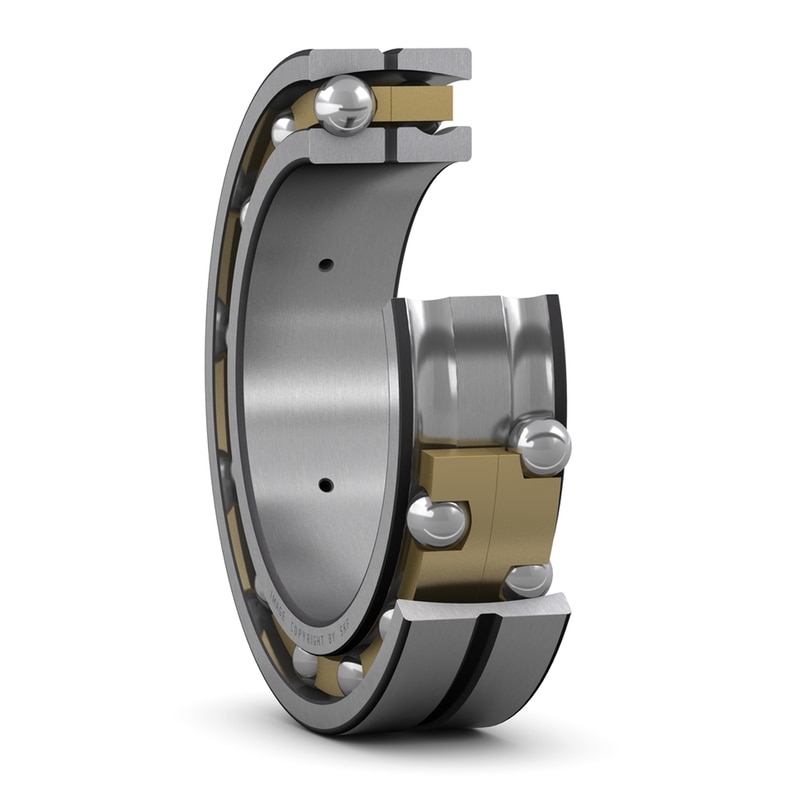

7014 CEGATNH/P4A

Super-precision, high-speed, E design, universally matchable single row angular contact ball bearingThese super-precision, high-speed, E design, single row angular contact ball bearings accommodate radial and axial loads acting simultaneously, where the axial load acts in one direction only. They are designed for high-speed operation and, compared to SKF B design high-speed bearings, have a slightly higher speed capability and can accommodate heavier loads. Being universally matchable, they can be used together in arrangements to provide effective load sharing, within a predetermined preload range, without the use of shims or similar devices.

- Very high running accuracy

- Accommodate very high speeds

- Universally matchable

Description

| Universal matching bearing(s) | Yes, back-to-back (<>), face-to-face (><) or tandem (>>) |

Dimensions

| d | 70 mm | Bore diameter |

|---|---|---|

| D | 110 mm | Outside diameter |

| B | 20 mm | Width |

| d1 | 84.3 mm | Shoulder diameter of inner ring (large side face) |

| d2 | 81.6 mm | Shoulder diameter of inner ring (small side face) |

| D1 | 95.32 mm | Shoulder diameter of outer ring (large side face) |

| r1,2 | min. 1.1 mm | Chamfer dimension |

| r3,4 | min. 0.6 mm | Chamfer dimension |

| a | 22.2 mm | Distance from side face to pressure point |

Abutment dimensions

| da | min. 76 mm | Diameter of shaft abutment |

|---|---|---|

| db | min. 76 mm | Diameter of shaft abutment |

| Da | max. 104 mm | Diameter of housing abutment |

| Db | max. 105.8 mm | Diameter of housing abutment |

| ra | max. 1 mm | Radius of fillet |

| rb | max. 0.6 mm | Radius of fillet |

| dn | 86.5 mm | Position of oil nozzle |

Calculation data

| Basic dynamic load rating | C | 23.8 kN |

|---|---|---|

| Basic static load rating | C0 | 18.3 kN |

| Fatigue load limit | Pu | 0.78 kN |

| Attainable speed for grease lubrication | 17 000 r/min | |

| Attainable speed for oil-air lubrication | 27 000 r/min | |

| Contact angle | α | 15 ° |

| Ball diameter | Dw | 9.525 mm |

| Number of balls (per bearing) | z | 25 |

| Reference grease quantity (per bearing) | Gref | 8.2 cm³ |

| Preload class A | GA | 130 N |

|---|---|---|

| Axial stiffness for preload A (sets of two brgs back-to-back or face-to-face) | 57 N/µm |

| Correction factor dependent on bearing series and size | f | 1.09 |

|---|---|---|

| Correction factor dependent on contact angle | f1 | 1 |

| Correction factor, preload class A | f2A | 1 |

| Correction factor for hybrid bearings | fHC | 1 |

| Calculation factor | f0 | 8.4 |

| Axial load factor (back-to-back, face-to-face) | Y0 | 0.92 |

| Radial load factor (back-to-back, face-to-face) | X1 | 1 |

| Radial load factor (back-to-back, face-to-face) | X2 | 0.72 |

| Radial load factor (back-to-back, face-to-face) | X0 | 1 |

Mass

| Mass | 0.61 kg |

Tolerances and clearances

Product details

- Tolerances: P4A, P4B, P4, PA9A, P2

- Clamping and fitting forces: D design, E design, B design

- Designation suffixes H, H1, L and L1 identify variants for direct oil-air lubrication.

Principles of bearing selection and application

- Chamfer dimensions

- Seat tolerances for standard conditions: shafts, housings

- Values for ISO tolerance classes: shafts, housings

- Speed dependent initial grease fill → Initial grease fill