Description

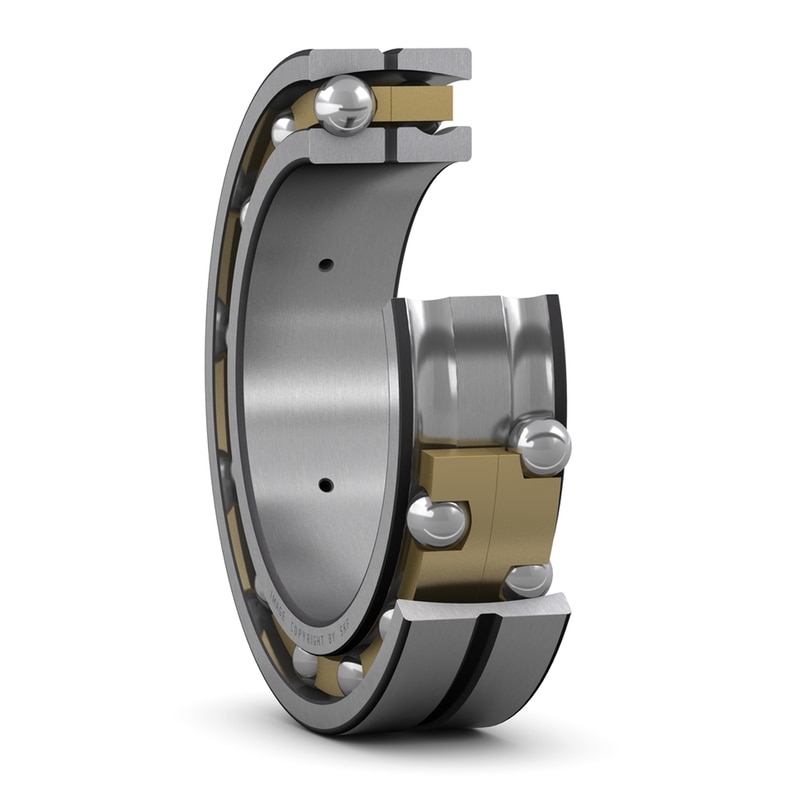

High temperature deep groove ball bearings are designed to operate reliably in high temperature environments, typically up to 350°C (660°F). They have several features that allow them to withstand these extreme conditions:

1. Material: High temperature bearings are typically made from heat-resistant stainless steel or other special alloys that can withstand high temperatures without losing their structural integrity.

2. Lubrication: These bearings are often lubricated with high temperature grease or oil that can withstand the elevated temperatures without breaking down or evaporating.

3. Cage: The cage, which holds the rolling elements in place, is usually made from heat-resistant materials such as stainless steel or brass. This ensures that the cage does not deform or melt under high temperature conditions.

4. Sealing: High temperature bearings may be equipped with special seals or shields that prevent the ingress of contaminants and protect the bearing from heat-related damage.

5. Clearance: The internal clearance of high temperature bearings is often adjusted to compensate for the expansion that occurs at high temperatures. This ensures that the bearing remains properly aligned and does not bind or seize.

Overall, high temperature deep groove ball bearings are designed to provide reliable and long-lasting performance in extreme heat conditions, making them suitable for applications such as ovens, kilns, and automotive exhaust systems.

High temperature deep groove ball bearings are commonly used in a variety of applications where the operating temperature is significantly higher than what standard bearings can handle. Some common applications include:

1. Ovens and Furnaces: High temperature bearings are used in the rotating components of industrial ovens and furnaces, where temperatures can reach several hundred degrees Celsius. These bearings ensure smooth and reliable operation in these extreme heat environments.

2. Automotive Exhaust Systems: Deep groove ball bearings are used in the turbochargers and exhaust gas recirculation (EGR) systems of automotive engines. These components can reach high temperatures due to the hot exhaust gases, and high temperature bearings ensure proper functioning and longevity in these conditions.

3. Kilns and Dryers: High temperature bearings are used in the rotating parts of kilns and dryers used in industries such as cement, ceramics, and paper. These bearings can withstand the high temperatures generated during the drying and firing processes.

4. Glass Manufacturing: Deep groove ball bearings are used in glass manufacturing equipment, such as glass tempering machines and glass annealing lehrs. These machines operate at high temperatures to shape and strengthen glass, and high temperature bearings are crucial for their reliable operation.

5. Steel Mills: High temperature bearings are used in the rolling mills and continuous casting machines of steel mills. These bearings can withstand the extreme heat generated during the steel production process.

6. Aerospace and Defense: High temperature bearings are used in aircraft engines, gas turbines, and other aerospace and defense applications where high temperatures are present. These bearings ensure reliable performance in critical components operating under extreme conditions.

Overall, high temperature deep groove ball bearings find application in various industries and equipment where reliable operation at elevated temperatures is required.