Description

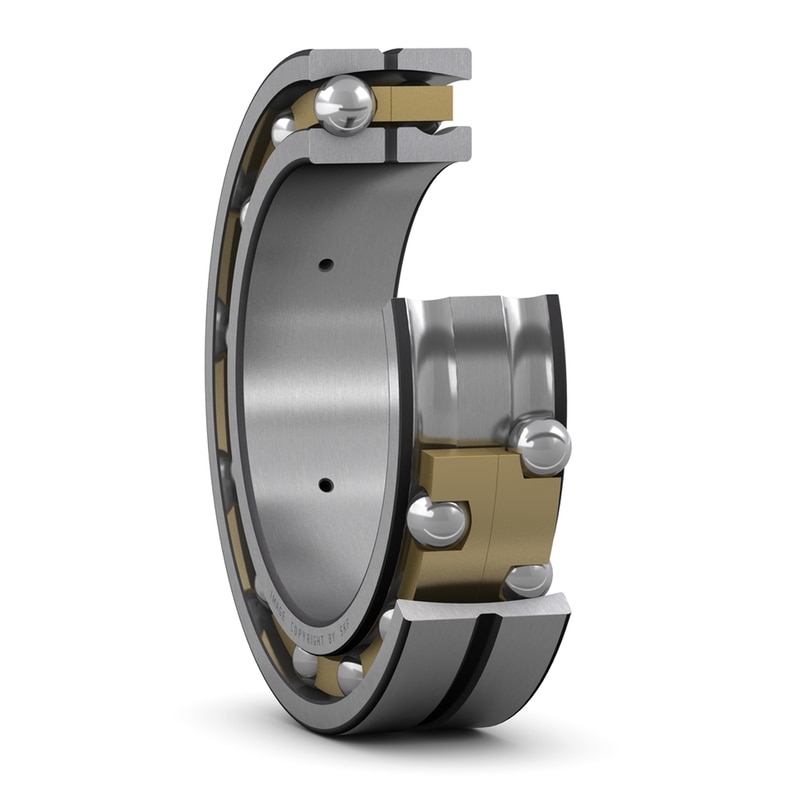

Double row tapered roller bearings have several features that make them suitable for various applications. Some of these features include:

1. High load capacity: Double row tapered roller bearings have a design that allows for a higher load capacity compared to single row tapered roller bearings. The two rows of rollers distribute the load evenly, reducing stress concentrations and increasing the bearing’s load-carrying capacity.

2. Radial and axial load capability: These bearings can accommodate both radial and axial loads simultaneously. The inner and outer rings are designed to provide axial guidance, making them suitable for applications where both radial and axial loads are present.

3. Tapered roller design: The tapered roller design of these bearings enables them to handle both radial and axial loads. The tapered shape of the rollers facilitates efficient distribution of the load along the roller length, resulting in improved load-carrying capacity and reduced friction.

4. High rigidity: Double row tapered roller bearings have a rigid design that provides high rigidity and stability. This ensures precise and accurate operation, even under heavy loads and high-speed conditions.

5. Space-saving design: Double row tapered roller bearings have a compact design compared to other types of bearings. This makes them suitable for applications where space is limited or where a compact design is desired.

6. Easy installation and maintenance: These bearings are typically designed for easy installation and maintenance. They often have separable inner and outer rings, which simplifies mounting and dismounting. Additionally, their design allows for easy lubrication access, contributing to efficient maintenance.

7. Versatile applications: Double row tapered roller bearings find application in various industries and machinery, including automotive, construction equipment, agricultural machinery, and industrial machinery. They are commonly used in applications that require both radial and axial load capability, such as wheel hubs, gearboxes, and transmissions.

8. Long service life: The design and materials used in double row tapered roller bearings contribute to their long service life. They are designed to withstand heavy loads and harsh operating conditions, ensuring reliable and durable performance.

Overall, the features of double row tapered roller bearings, including their high load capacity, radial and axial load capability, tapered roller design, high rigidity, space-saving design, easy installation and maintenance, versatile applications, and long service life, make them a preferred choice in various industries and applications where both radial and axial loads need to be accommodated.

Double row tapered roller bearings find application in a wide range of industries and machinery where both radial and axial loads need to be accommodated. Some common applications of double row tapered roller bearings include:

1. Automotive industry: These bearings are used in automotive applications such as wheel hubs, transmissions, and differentials. They can handle the radial and axial loads generated by vehicle operation and provide reliable and efficient power transmission.

2. Construction equipment: Double row tapered roller bearings are utilized in construction machinery such as excavators, loaders, and cranes. They provide reliable and smooth operation under heavy loads, ensuring stability and durability.

3. Industrial machinery: These bearings find application in various industrial machinery, including gearboxes, machine tools, and printing presses. They can handle the combined radial and axial loads encountered in these applications, providing precise and efficient operation.

4. Agricultural machinery: Double row tapered roller bearings are used in agricultural machinery such as tractors, combines, and harvesters. They can handle the heavy loads and harsh operating conditions commonly found in agricultural applications, ensuring reliable and efficient operation.

5. Mining equipment: These bearings are employed in mining machinery such as crushers, screens, and conveyors. They can handle the heavy loads and harsh operating conditions commonly encountered in the mining industry, ensuring reliable and efficient operation.

6. Railway industry: Double row tapered roller bearings are used in railway applications such as wheelsets and gearboxes. They can handle the radial and axial loads generated by train operation and provide reliable and efficient power transmission.

7. Steel mills: These bearings find application in steel mills, where they support the rolling mills and other heavy machinery involved in the steel manufacturing process. They can withstand the heavy loads and high temperatures typically encountered in steel mill operations.

8. Wind turbines: These bearings are utilized in wind turbine generators, where they support the rotation of the rotor. They can handle the combined radial and axial loads generated by wind power generation, ensuring reliable and efficient operation.

9. Papermaking machinery: Double row tapered roller bearings are used in papermaking machinery, including paper machines and pulpers. They can handle the heavy loads and high speeds involved in the papermaking process, ensuring reliable and efficient operation.

10. Marine industry: These bearings find application in the marine industry, including ship propulsion systems and deck machinery. They can handle the radial and axial loads generated by marine operations, ensuring reliable and efficient power transmission.

In summary, double row tapered roller bearings are utilized in various industries and machinery where both radial and axial loads need to be accommodated. Their applications include automotive, construction equipment, industrial machinery, agricultural machinery, mining equipment, railway industry, steel mills, wind turbines, papermaking machinery, and the marine industry.

Reviews

There are no reviews yet.