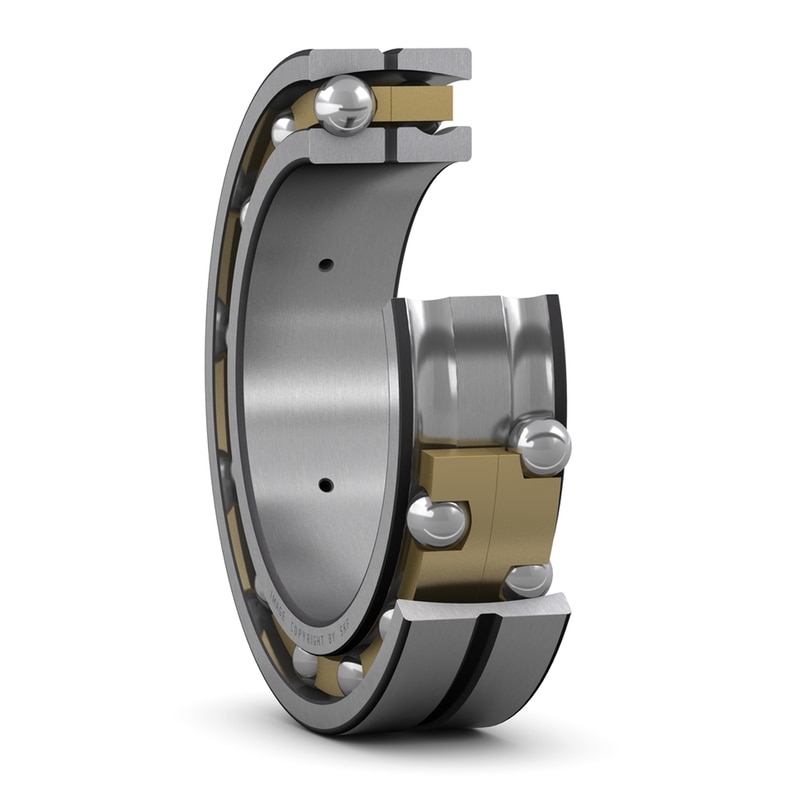

7015 CD/HCP4AL

Super-precision, high-capacity, single row angular contact ball bearing suitable for direct oil-air lubrication25° contact angle, accommodate radial and axial loads acting simultaneously, where the axial load acts in one direction only. They are designed to accommodate heavy loads at relatively high speeds under low to moderate operating temperatures. They have two lubrication holes, an annular groove, and two annular O-ring grooves in their outer rings.

- Suitable for direct oil-air lubrication

- Very high running accuracy

- Very high load carrying capacity

- Relatively high speed and stiffness

Description

| Universal matching bearing(s) | No |

Dimensions

| d | 75 mm | Bore diameter |

|---|---|---|

| D | 115 mm | Outside diameter |

| B | 20 mm | Width |

| d1 | 87.3 mm | Shoulder diameter of inner ring (large side face) |

| d2 | 87.3 mm | Shoulder diameter of inner ring (small side face) |

| D1 | 102.7 mm | Shoulder diameter of outer ring (large side face) |

| b | 1.8 mm | Width of lubrication groove |

| C1 | 10.9 mm | Distance from outer ring side face to lubrication groove / lubrication hole |

| C2 | 3.9 mm | Distance from outer ring side face to O-ring groove |

| C3 | 3.4 mm | Distance from outer ring side face to O-ring groove |

| r1,2 | min. 1.1 mm | Chamfer dimension |

| r3,4 | min. 0.6 mm | Chamfer dimension |

| a | 22.8 mm | Distance from side face to pressure point |

Abutment dimensions

| da | min. 81 mm | Diameter of shaft abutment |

|---|---|---|

| db | min. 81 mm | Diameter of shaft abutment |

| Da | max. 109 mm | Diameter of housing abutment |

| Db | max. 111 mm | Diameter of housing abutment |

| ra | max. 1 mm | Radius of fillet |

| rb | max. 0.6 mm | Radius of fillet |

| dn | 90 mm | Position of oil nozzle |

Calculation data

| Basic dynamic load rating | C | 52.7 kN |

|---|---|---|

| Basic static load rating | C0 | 49 kN |

| Fatigue load limit | Pu | 1.5 kN |

| Attainable speed for grease lubrication | 14 000 r/min | |

| Attainable speed for oil-air lubrication | 22 000 r/min | |

| Contact angle | α | 15 ° |

| Ball diameter | Dw | 12.7 mm |

| Number of balls (per bearing) | z | 20 |

| Reference grease quantity (per bearing) | Gref | 8.4 cm³ |

| Preload class A | GA | 200 N |

|---|---|---|

| Axial stiffness for preload A (sets of two brgs back-to-back or face-to-face) | 93 N/µm | |

| Preload class B | GB | 400 N |

| Axial stiffness for preload B (sets of two brgs back-to-back or face-to-face) | 128 N/µm | |

| Preload class C | GC | 800 N |

| Axial stiffness for preload C (sets of two brgs back-to-back or face-to-face) | 179 N/µm | |

| Preload class D | GD | 1 600 N |

| Axial stiffness for preload D (sets of two brgs back-to-back or face-to-face) | 260 N/µm |

| Correction factor dependent on bearing series and size | f | 1.14 |

|---|---|---|

| Correction factor dependent on contact angle | f1 | 1 |

| Correction factor, preload class A | f2A | 1 |

| Correction factor, preload class B | f2B | 1.02 |

| Correction factor, preload class C | f2C | 1.05 |

| Correction factor, preload class D | f2D | 1.09 |

| Correction factor for hybrid bearings | fHC | 1.02 |

| Calculation factor | f0 | 15.7 |

Mass

| Mass | 0.53 kg |

Tolerances and clearances

Product details

- Tolerances: P4A, P4B, P4, PA9A, P2

- Clamping and fitting forces: D design, E design, B design

- Designation suffixes H, H1, L and L1 identify variants for direct oil-air lubrication.

Principles of bearing selection and application

- Chamfer dimensions

- Seat tolerances for standard conditions: shafts, housings

- Values for ISO tolerance classes: shafts, housings

- Speed dependent initial grease fill → Initial grease fill