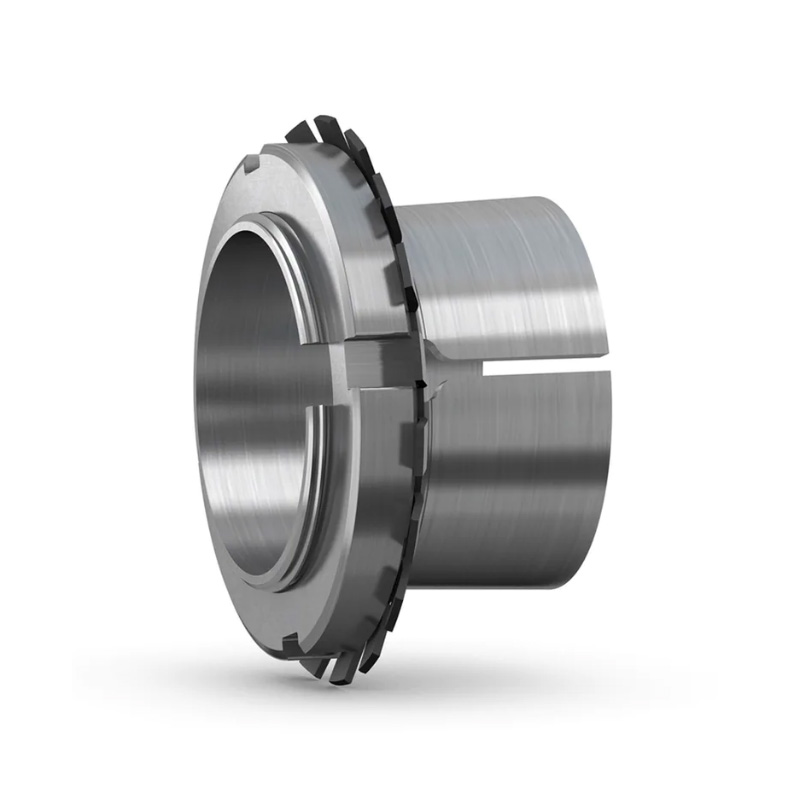

Description

Adapter sleeves are cylindrical sleeves that are used to mount bearings with tapered bores onto cylindrical shafts. They are commonly used in applications where it is necessary to easily mount and dismount bearings for maintenance or replacement purposes. Here are some key features of adapter sleeves:

1. Tapered bore alignment: Adapter sleeves are designed to match the tapered bore of the bearing they are used with. This allows for easy alignment of the bearing on the shaft, ensuring proper load distribution and reducing the risk of premature wear or damage.

2. Easy installation and removal: Adapter sleeves are typically split sleeves, which means they can be easily installed or removed from the shaft by tightening or loosening the locking nut. This simplifies the mounting and dismounting process, saving time and effort during maintenance or replacement tasks.

3. Axial displacement capability: Adapter sleeves have a slotted design that allows for axial displacement of the bearing along the shaft. This feature is useful for adjusting the position of the bearing to achieve proper clearance or preload, optimizing the performance and lifespan of the bearing.

4. Secure locking mechanism: Adapter sleeves usually have a locking nut that, when tightened, securely locks the sleeve onto the shaft. This ensures that the bearing remains in place during operation, even under heavy loads or vibrations.

5. Wide range of sizes and designs: Adapter sleeves are available in various sizes and designs to accommodate different shaft diameters and bearing types. This versatility allows for their use in a wide range of applications, from small machines to large industrial equipment.

6. Corrosion resistance: Adapter sleeves are often made from high-quality materials, such as stainless steel or corrosion-resistant steel, to withstand harsh operating environments and resist corrosion. This ensures their durability and long service life.

7. Cost-effective solution: Adapter sleeves provide a cost-effective solution for mounting and dismounting bearings compared to other methods, such as using hydraulic tools or specialized equipment. They are relatively simple and straightforward to use, reducing the need for additional tools or complex procedures.

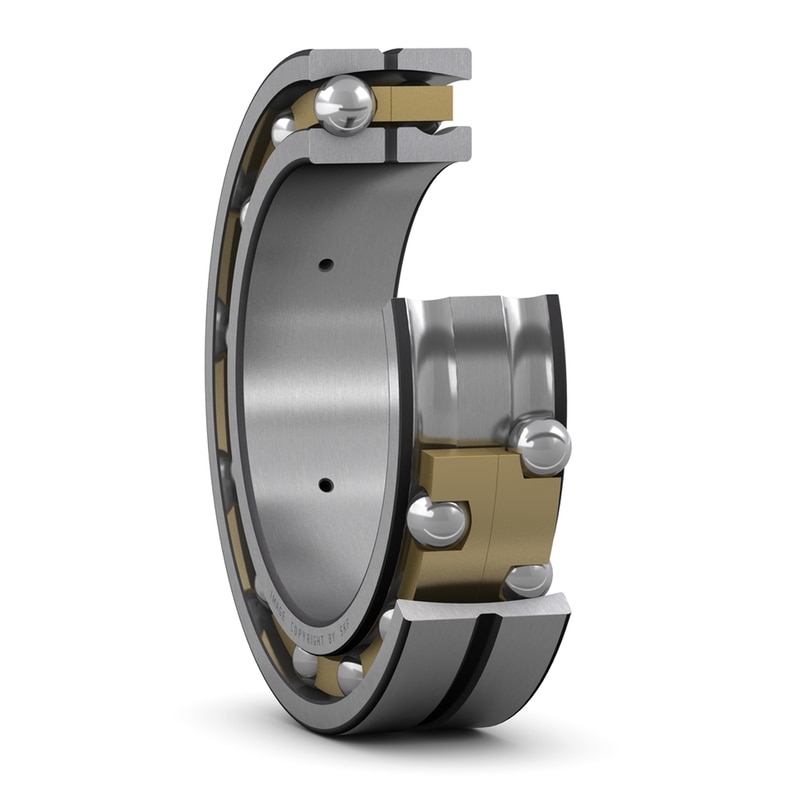

8. Compatibility with different bearing types: Adapter sleeves can be used with various types of bearings, including ball bearings, spherical roller bearings, and tapered roller bearings. This versatility makes them suitable for a wide range of applications across different industries.

Overall, adapter sleeves offer a convenient and efficient method for mounting and dismounting bearings with tapered bores onto cylindrical shafts. Their features, such as tapered bore alignment, easy installation and removal, axial displacement capability, secure locking mechanism, and wide range of sizes and designs, make them a popular choice in many industries for their versatility and cost-effectiveness.

Adapter sleeves have a wide range of applications in various industries. Here are some common applications:

1. Industrial machinery: Adapter sleeves are used in various types of industrial machinery, such as pumps, compressors, conveyors, and gearboxes. They allow for easy mounting and dismounting of bearings, facilitating maintenance and replacement tasks.

2. Mining and construction equipment: In the mining and construction industries, adapter sleeves are used in equipment such as crushers, screens, and excavators. They enable quick and efficient bearing installation and removal, reducing downtime and improving productivity.

3. Power transmission systems: Adapter sleeves are commonly used in power transmission systems, including motors, generators, and gear drives. They provide a secure and reliable connection between the bearing and the shaft, ensuring efficient power transfer.

4. Automotive industry: Adapter sleeves find application in automotive components, such as wheel hubs, transmission systems, and engine components. They allow for easy bearing installation and removal, facilitating maintenance and repair tasks.

5. Agricultural machinery: In the agricultural sector, adapter sleeves are used in equipment such as tractors, harvesters, and irrigation systems. They enable quick and easy mounting and dismounting of bearings, reducing downtime and improving operational efficiency.

6. Food and beverage industry: Adapter sleeves are utilized in food and beverage processing equipment, such as mixers, conveyors, and packaging machines. They provide a reliable and hygienic mounting solution for bearings, ensuring safe and efficient operation.

7. Marine and offshore applications: In the marine and offshore industries, adapter sleeves are used in equipment such as ship engines, propeller shafts, and winches. They allow for easy bearing installation and removal, facilitating maintenance and repair tasks in challenging marine environments.

8. Railways: Adapter sleeves find application in railway systems, particularly in locomotives and railcar axles. They enable quick and efficient mounting and dismounting of bearings, ensuring reliable and smooth movement.

9. Pulp and paper industry: In the pulp and paper industry, adapter sleeves are used in equipment such as paper machines, pulp digesters, and drying cylinders. They provide a secure and efficient mounting solution for bearings, ensuring smooth operation and high-quality paper production.

10. Wind turbines: Adapter sleeves are used in wind turbines to mount bearings on the turbine shaft. They allow for easy installation and removal of bearings, facilitating maintenance and repair tasks in wind energy systems.

Overall, adapter sleeves have diverse applications in various industries where bearings need to be mounted and dismounted quickly and efficiently. Their versatility, ease of use, and cost-effectiveness make them a popular choice for many different types of equipment and machinery.