Description

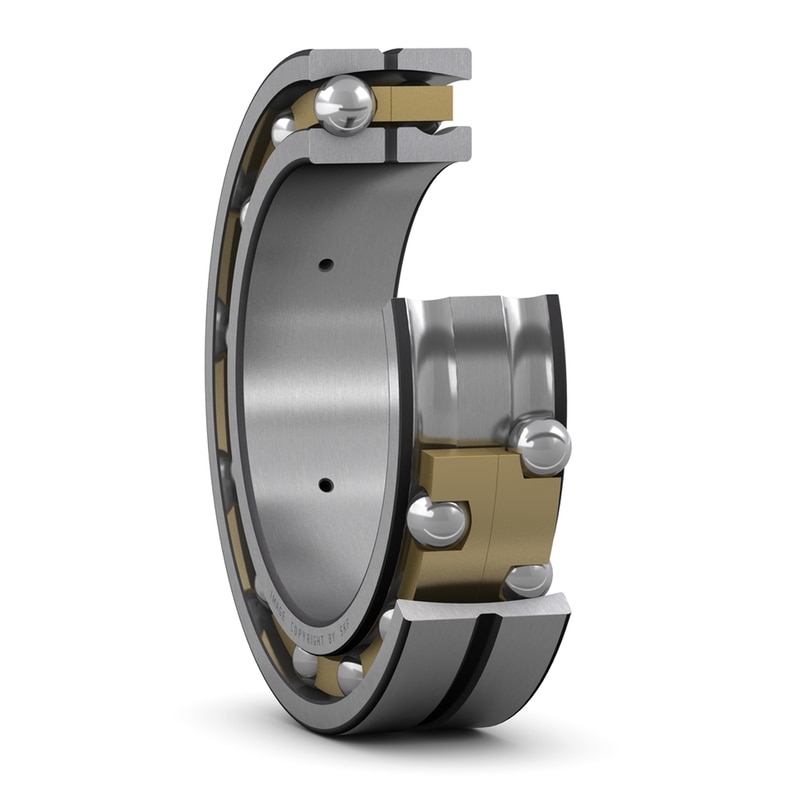

Single row full complement cylindrical roller bearings have several key features that make them suitable for various applications. Some of these features include:

1. Maximum load capacity: Single row full complement cylindrical roller bearings have a design that allows for a higher load capacity compared to other types of bearings. This is because they utilize a full complement of cylindrical rollers, which distribute the load evenly across the bearing’s length. This feature makes them particularly suitable for applications with heavy radial loads.

2. High radial stiffness: These bearings have a rigid design that provides high radial stiffness. This means that they can withstand and maintain their shape under heavy loads, ensuring stable and precise operation in applications that require minimal deflection or deformation.

3. Space-saving design: Single row full complement cylindrical roller bearings have a compact design due to the absence of a cage. This allows for a more compact overall bearing arrangement, making them suitable for applications with limited space or where a compact design is desired.

4. Enhanced operational reliability: The full complement of cylindrical rollers in these bearings ensures improved load distribution and reduced stress concentration. This results in enhanced operational reliability and increased bearing life, even under heavy load conditions.

5. Easy installation and maintenance: Single row full complement cylindrical roller bearings are typically designed for easy installation and maintenance. They often have separable inner and outer rings, which simplifies mounting and dismounting. Additionally, their design allows for easy lubrication access, contributing to efficient maintenance.

6. Suitable for high-speed applications: These bearings can be designed to accommodate high speeds, depending on the specific design and configuration. This makes them suitable for applications that require both high load capacity and high-speed operation, such as machine tools or power transmission systems.

7. Versatile applications: Single row full complement cylindrical roller bearings find application in various industries and machinery, including mining, construction equipment, wind turbines, industrial gearboxes, and steel mills. They are commonly used in heavy-duty applications that require reliable and efficient operation under demanding conditions.

Overall, the features of single row full complement cylindrical roller bearings, including their high load capacity, radial stiffness, space-saving design, operational reliability, ease of installation and maintenance, suitability for high-speed applications, and versatile applications, make them a preferred choice in many industries where heavy radial loads and compact design are required.

Single row full complement cylindrical roller bearings find application in various industries and machinery where heavy radial loads and compact design are required. Some common applications include:

1. Construction equipment: These bearings are used in construction machinery such as excavators, bulldozers, and cranes. They provide reliable and efficient operation under heavy loads, ensuring smooth movement and stability.

2. Mining equipment: Single row full complement cylindrical roller bearings are used in mining machinery, including crushers, screens, and conveyors. They can handle the heavy loads and harsh operating conditions commonly found in the mining industry.

3. Wind turbines: These bearings are employed in wind turbine generators, where they support the rotation of the rotor. The high load capacity and compact design of these bearings make them suitable for the demanding conditions of wind power generation.

4. Industrial gearboxes: Single row full complement cylindrical roller bearings are used in industrial gearboxes, which are critical components in various applications, including manufacturing, power generation, and transportation. They provide reliable and efficient power transmission, even under heavy loads.

5. Steel mills: These bearings find application in steel mills, where they support the rolling mills and other heavy machinery involved in the steel manufacturing process. They can withstand the heavy loads and high temperatures typically encountered in steel mill operations.

6. Machine tools: Single row full complement cylindrical roller bearings are used in machine tools, such as lathes, milling machines, and grinding machines. They provide precise and stable operation, ensuring accurate machining processes.

7. Printing machinery: These bearings are utilized in printing machinery, including offset printers and digital printers. They support the movement of printing cylinders or rollers, ensuring precise and consistent printing quality.

8. Papermaking machinery: Single row full complement cylindrical roller bearings are used in papermaking machinery, including paper machines and pulpers. They provide reliable and efficient operation under the heavy loads and high speeds involved in the papermaking process.

9. Textile machinery: These bearings find application in textile machinery, such as spinning machines and weaving machines. They support the rotating components, ensuring smooth and precise operation in the textile manufacturing process.

123. Agricultural machinery: Single row full complement cylindrical roller bearings are used in various agricultural machinery, including tractors, harvesters, and irrigation systems. They provide reliable operation under heavy loads, ensuring efficient agricultural operations.

In summary, single row full complement cylindrical roller bearings are utilized in a wide range of industries and machinery where heavy radial loads and compact design are required. Their applications include construction equipment, mining equipment, wind turbines, industrial gearboxes, steel mills, machine tools, printing machinery, papermaking machinery, textile machinery, and agricultural machinery.