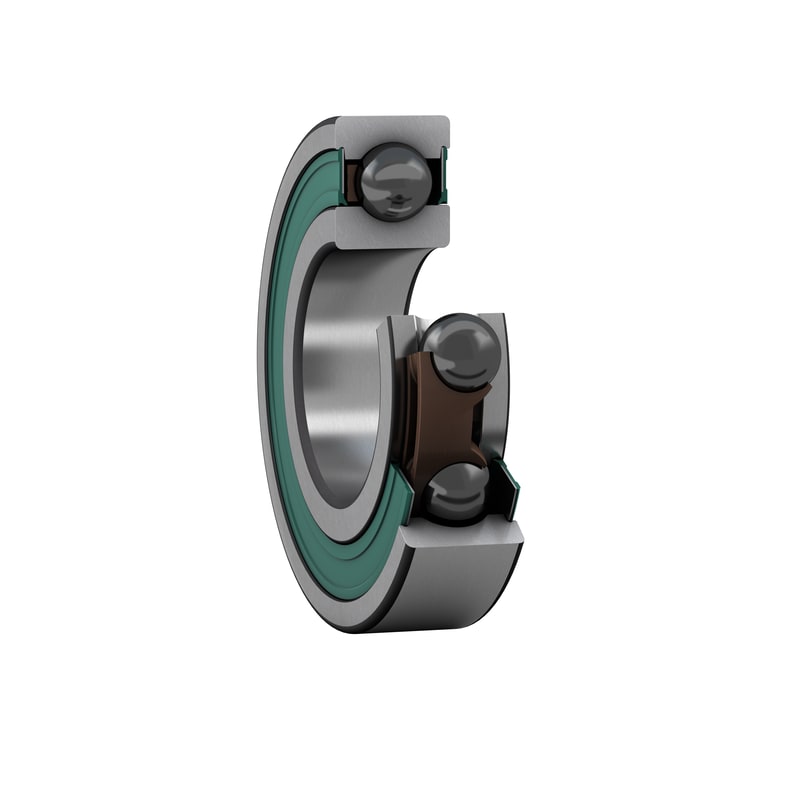

6006-2RZTN9/HC5C3WT

Hybrid deep groove ball bearing with seals on both sidesHybrid single row deep groove ball bearings with seals on both sides have rings made of bearing steel and rolling elements made of bearing grade silicon nitride (Si3N4), which make the bearings electrically insulating. The integral sealing can significantly prolong bearing service life because it keeps lubricant in the bearings and contaminants out. The silicon nitride elements not only provide protection from electric current damage but also, when compared to same-sized bearings with steel rolling elements, provide enhanced bearing performance, extended bearing service life, higher speed capability, high wear-resistance, high bearing stiffness, reduced risk of smearing and false brinelling, and less sensitivity to temperature gradients, making them suitable for use in dificult conditions and contaminated environments.

- Protected against electric current damage

- Integral sealing prolongs bearing service life

- Especially suited for use in difficult conditions and contaminated environments

- Typical benefits of single row deep groove ball bearings

Description

Dimensions

| d | 30 mm | Bore diameter |

|---|---|---|

| D | 55 mm | Outside diameter |

| B | 13 mm | Width |

| d1 | ≈ 38.2 mm | Shoulder diameter inner ring |

| D2 | ≈ 49 mm | Recess diameter outer ring shoulder |

| r1,2 | min. 1 mm | Chamfer dimension |

Abutment dimensions

| da | min. 34.6 mm | Abutment diameter shaft |

|---|---|---|

| da | max. 38.1 mm | Abutment diameter shaft |

| Da | max. 50.4 mm | Abutment diameter housing |

| ra | max. 0.3 mm | Fillet radius |

Calculation data

| Basic dynamic load rating | C | 13.3 kN |

|---|---|---|

| Basic static load rating | C0 | 8.3 kN |

| Fatigue load limit | Pu | 0.255 kN |

| Reference speed | 30 000 r/min | |

| Limiting speed | 16 000 r/min | |

| Calculation factor | kr | 0.025 |

| Calculation factor | f0 | 14.7 |

Mass

| Mass bearing | 0.11 kg |

Tolerances and clearances

Bearing data

Bearing interfaces