Description

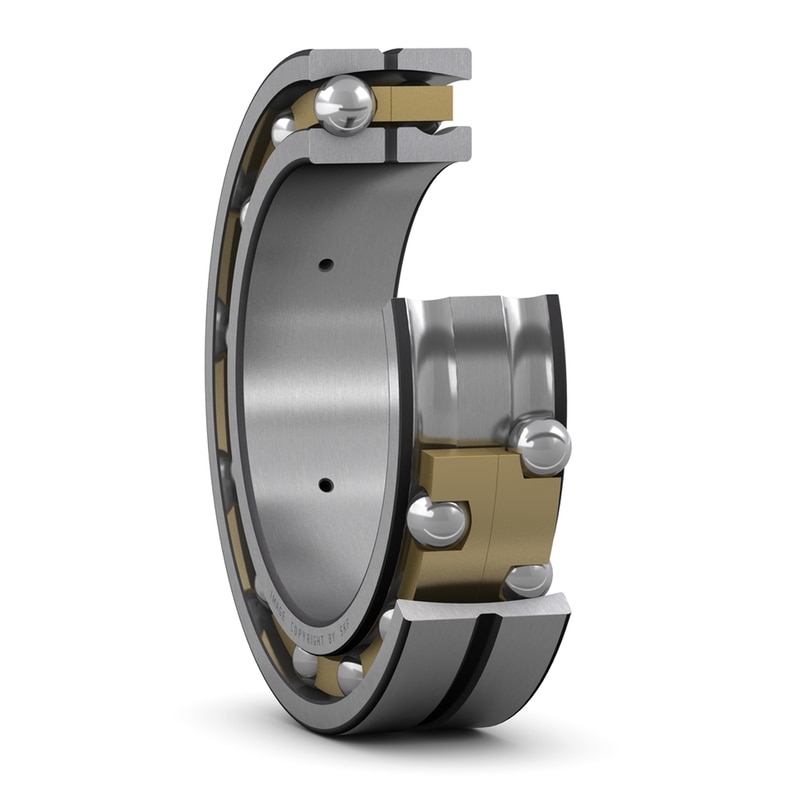

Double row Tapered Roller Bearings with WRM consist of two single row tapered roller bearings mounted face-to-face. The inner and outer rings of each bearing are tapered and the rollers are arranged in rows at an angle to the bearing axis. This design allows for high radial and axial loads to be supported. The two rows of rollers also provide increased stiffness and rigidity compared to a single row bearing. The bearings are usually separated by a spacer or inner ring to control the axial clearance. The bearings can be adjusted to provide a pre-load or clearance during installation.

Double row tapered roller bearings have several features that make them suitable for a wide range of applications. Some of the key features include:

1. High load capacity: Double row Tapered Roller Bearings with WRM have a high load capacity, which makes them suitable for heavy-duty applications.

2. Axial rigidity: Double row Tapered Roller Bearings with WRM have high axial rigidity, which helps them maintain their shape and prevent deformation under heavy loads.

3. Precision:Double row Tapered Roller Bearings with WRM are designed to provide high precision and accuracy, which makes them suitable for applications that require tight tolerances.

4. Low friction: Double row Tapered Roller Bearings with WRM have low friction, which helps reduce energy consumption and improve efficiency.

5. Durability: Double row Tapered Roller Bearings with WRM are designed to be durable and long-lasting, which makes them suitable for applications that require high reliability and uptime.

6. Easy maintenance: Double row Tapered Roller Bearings with WRM are easy to maintain and repair, which helps reduce downtime and maintenance costs.

Overall, the features of double row tapered roller bearings make them suitable for a wide range of applications, including automotive, industrial, and aerospace applications.